Complete varieties and specifications: meet the diversified needs of various scenarios

Complete varieties and specifications: meet the diversified needs of various scenarios

ABOUT US

Company founded in

Registered capital

Offices, dealerships

Heilongjiang Ouxinte Mining Machinery Equipment Co., Ltd.

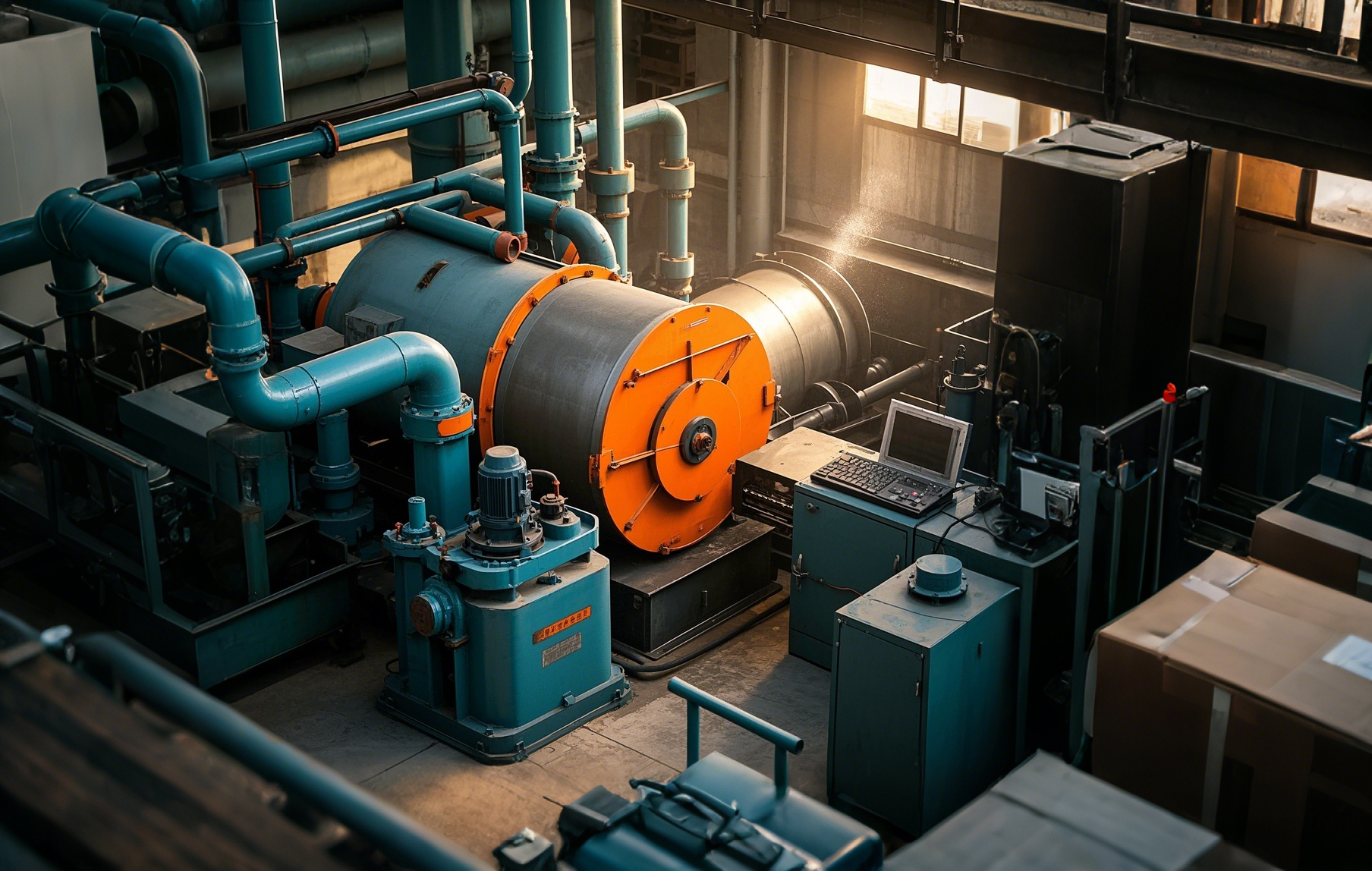

Heilongjiang Ouxinte Mining Machinery Equipment Co., Ltd. is a sales company integrating the research and development, production, and sales of mining machinery. The company has more than 40 offices or dealerships in more than 20 provinces and cities in China, and its products are sold to more than 40 countries and regions, including Chile, Australia, New Zealand, Sweden, the United Kingdom, France, Germany, Greece, Russia, Kazakhstan, the UAE, South Africa, Ethiopia, Japan, South Korea, and Taiwan. The company adheres to market orientation, focuses on product quality, and takes the customer as the supreme principle. It implements full-process quality tracking and monitoring from production to after-sales service, and has cultivated a team of technical development and production management. Its management philosophy and rigorous management measures ensure the quality and advantages of products. We warmly welcome domestic and foreign merchants to contact us by mail, phone, or letter to discuss business. We will provide you with excellent service.

Application Areas

Focusing on customer concerns and addressing industry needs

-

High-speed railway

High-speed railway

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc. -

Power Cable

Power Cable

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc. -

Communication

Communication

Communication

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc. -

Building bridges

Building bridges

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc. -

Marine engineering

Marine engineering

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc. -

Automotive industry

Automotive industry

The product is widely used in various industries such as mining, metallurgy, construction, road construction, chemical industry, energy industry, etc.

-

Service underwriting

Launch a comprehensive underwriting plan for mining machinery and equipment services

+Service underwriting

Launch a comprehensive underwriting plan for mining machinery and equipment services

Mining machinery and equipment play a crucial role in mining operations, but their operation faces various risks. To help mining enterprises cope with these risks, a comprehensive mining machinery and equipment service underwriting plan has been launched, aiming to provide reliable risk protection for enterprises and ensure stable production and operation.

-

Maintenance

Equipment longevity relies on maintenance, and efficiency improvement is guaranteed

+Maintenance

Equipment longevity relies on maintenance, and efficiency improvement is guaranteed

Daily inspection of lubrication system, cleaning of equipment surfaces, tightening of loose bolts to ensure smooth operation. Replace the filter element and hydraulic oil periodically, calibrate the transmission components, and detect the wear status of key vulnerable parts.

-

Engineering case

Cover more than 30 countries and regions around the world

+Engineering case

Cover more than 30 countries and regions around the world

The underwriting business of mining machinery and equipment has successfully covered more than 30 countries and regions around the world, and has served thousands of well-known domestic and foreign customers in total.

-

Talent Recruitment

Everyone is a talent, and everyone can become a useful person.

+Talent Recruitment

Everyone is a talent, and everyone can become a useful person.

Firmly establish the concept that human resources are the primary resource. Adhere to the tenet of "respecting the value of talents, shaping the quality of talents, and devoting to the growth of talents", put people first, and work in the same direction to achieve the common development of the company and employees.

Focusing on real-time corporate dynamics and releasing new authoritative information

Apr 23,2025

Apr 23,2025

Apr 23,2025

Apr 23,2025

Apr 23,2025

Apr 23,2025

Adhering to market orientation and focusing on product quality

The company has more than 40 offices or dealerships in more than 20 provinces and cities in China, and its products are sold to more than 40 countries and regions, including Chile, Australia, New Zealand, Sweden, the United Kingdom, France, Germany, Greece, Russia, Kazakhstan, the UAE, South Africa, Ethiopia, Japan, South Korea, and Taiwan.

Customer service hotline

Email:77387517@qq.com

Website:http://www.xbtgc.cn

Address: Sheli Village, Taiping Village, Sheli Original Steel Plant, Acheng District, Harbin City

Official public account

Website construction:www.300.cn