What are the main factors affecting the efficiency of ball mills in ore dressing?

Publish Time:

2020-08-10

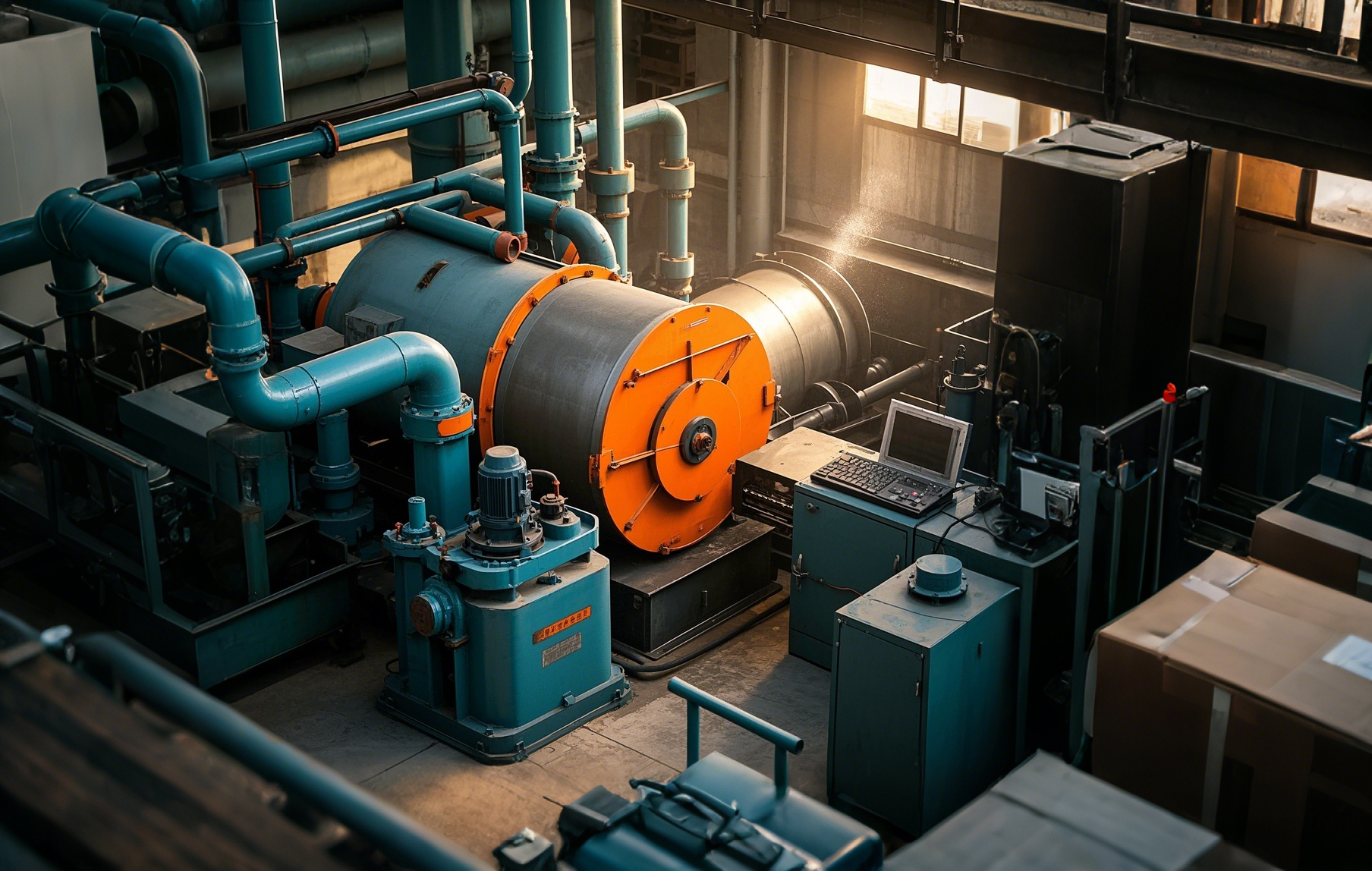

Views:

In mineral processing, ball mills typically use the compressive and frictional forces between grinding media such as steel balls to grind materials. Ball mills are used in the grinding of iron ore, gold ore, and copper ore, as well as in the metal smelting, ceramics, fine chemicals, cement production, and power generation industries for crushing and pulverizing operations. However, ball mills have long suffered from problems such as high energy consumption, rapid steel wear, and low grinding efficiency.

What are the main factors affecting the working efficiency of ball mills in ore dressing equipment?

Ore dressing ball mills typically use the squeezing and frictional forces between grinding media such as steel balls to grind materials. They are used in iron ore, gold ore, and copper ore grinding, as well as in metal smelting, ceramic products, fine chemicals, cement production lines, and power plants for crushing and pulverizing operations. However, ball mills have long suffered from high energy consumption, rapid steel wear, and low grinding efficiency.

What are the main factors affecting the working efficiency of ball mills in ore dressing equipment? How do these factors arise? How to improve the working efficiency of ball mills in ore dressing equipment?

1. Unreasonable matching of grinding media grades and the number of balls loaded. The specifications and loading of grinding media are not selected according to the specific properties of different materials, resulting in a low output coefficient of the ball mill equipment (output coefficient = output/loading), generally between 0.3 and 0.9.

2. The ore is not graded according to the energy required for grinding during the grinding process.

3. When materials with different physical and chemical properties are mixed and ground, impurities in the materials are not screened, and materials with excessively large volumes are included, such as stones mixed in coal.

4. Unreasonable work scheduling and peripheral supporting facilities adjustments. The ventilation performance, drying degree, and pulverizing output are not matched, resulting in unnecessary energy consumption increase.

5. The grinding media does not have sufficient wear resistance and strength. After several months of operation, the out-of-round rate increases, and the pulverizing output gradually decreases.

Methods and concepts for improving grinding efficiency

1. Optimize the grading and loading of steel balls and other grinding media: Based on the specific situation of the particle size distribution of the material, the impact force required for grinding, and the required fineness of the outlet, determine the shape, size, and loading of grinding media of different specifications to improve the grinding speed.

2. Optimize the design and placement of the mill liner of the ore dressing equipment to achieve graded grinding: According to the movement law of materials of different particle sizes in the grinding process in the mill, improve the liner combination and operation method to improve the throwing and falling of steel balls and other grinding media and the highest falling point, so that the grinding media self-adjusts along the length direction of the mill according to the particle size distribution specification to achieve positive grading and energy supply.

3. Optimization of the operating environment: According to the unique properties of various ores (water content, grindability, electrostatic adsorption, etc.), through multi-faceted and multiple comprehensive experiments, reasonably adjust the mill differential pressure, outlet temperature, material supply, and separation effectiveness of the ore dressing equipment according to the experimental results, establish standardized and regular parameter control standards, and keep the ball mill of the ore dressing equipment in good operation under output.

Keyword:

Learn More

Focusing on real-time corporate dynamics and releasing new authoritative information

Adhering to market orientation and focusing on product quality

The company has more than 40 offices or dealerships in more than 20 provinces and cities in China, and its products are sold to more than 40 countries and regions, including Chile, Australia, New Zealand, Sweden, the United Kingdom, France, Germany, Greece, Russia, Kazakhstan, the UAE, South Africa, Ethiopia, Japan, South Korea, and Taiwan.

Customer service hotline

Email:77387517@qq.com

Website:http://www.xbtgc.cn

Address: Sheli Village, Taiping Village, Sheli Original Steel Plant, Acheng District, Harbin City

Official public account

Website construction:www.300.cn