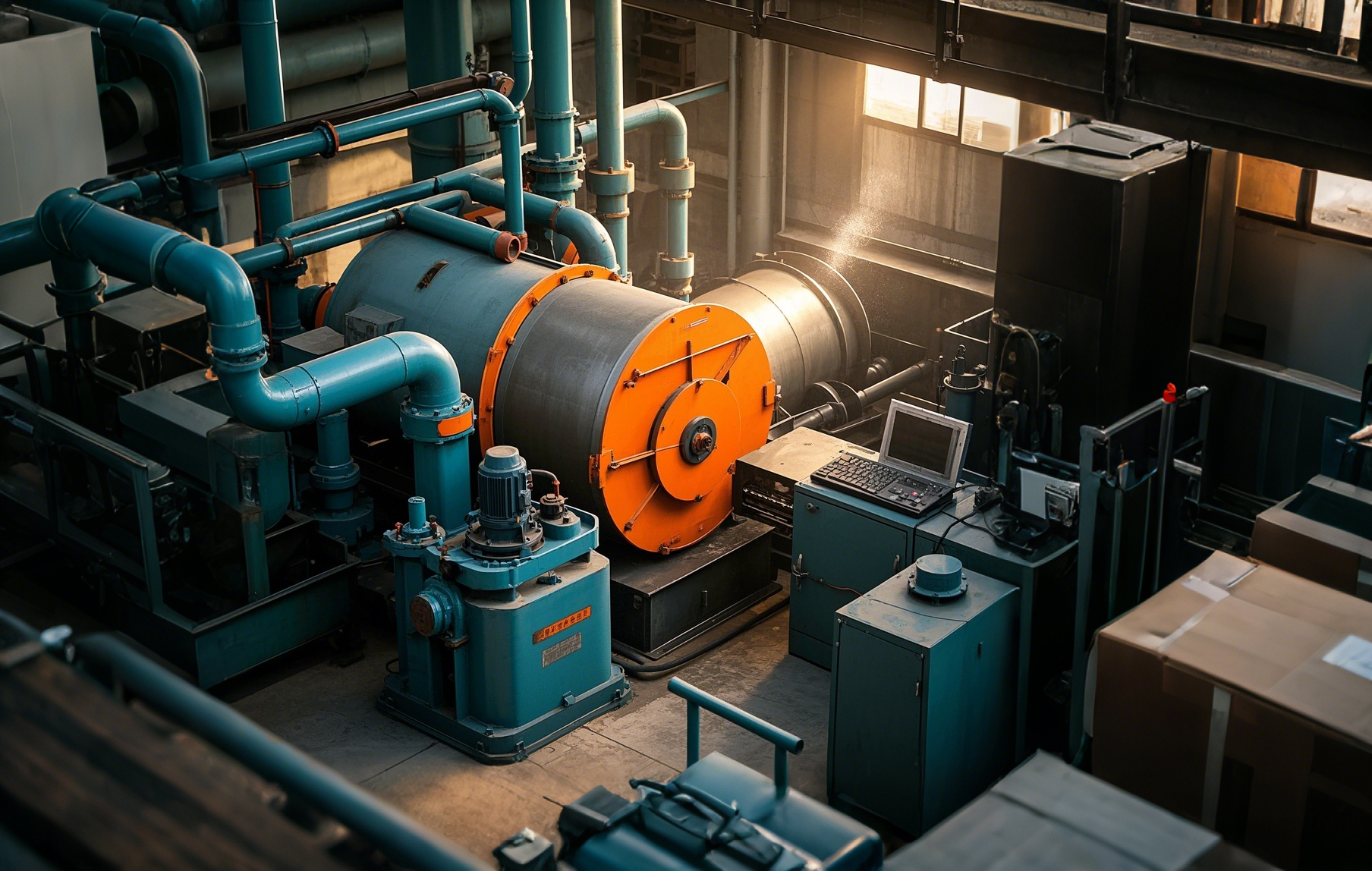

Vertical ball mill

Vertical ball mills are suitable for grinding and dispersing coarse, hard, or pseudoplastic materials. Materials ground by vertical ball mills have uniform and fine particle sizes. Vertical ball mills can also mix several materials very uniformly.

Working principle

The grinding media are driven by the stirring shaft to perform forced mechanical shearing and grinding. The material is pumped from the bottom filter screen and pipeline of the grinding cylinder to the top of the grinding cylinder, allowing the material and media to fully contact and grind, completing one cycle until the required fineness is reached.

Equipment advantages

Vertical ball mills integrate material classification and grinding. The grinding media impact is intense, suitable for high-viscosity, difficult-to-grind materials such as high-abrasion carbon black. Compared with other ball mills, it has the following advantages:

1. Strong ventilation and drying capacity, using kiln tail waste gas to dry the moisture in the raw materials;

2. No dead corners in the grinding cylinder, good homogeneity, less equipment, simple operation;

3. Special stirring shaft structure, increasing the media collision rate, improving the grinding frequency;

4. Convenient production adjustment and control, strong adaptability to various performance raw materials;

5. Double-layer cylinder body, special cooling circulation path, good cooling performance, fast discharge, easy cleaning;

6. Less system leakage, reducing the specifications, investment, and power consumption of the electrostatic precipitator for treating waste gas.

Use and maintenance

1. Place the equipment flat on the prepared foundation and fasten it with bolts.

2. Before starting, check whether all rotating parts are flexible, whether the motor electrical wiring terminals are firm and reliable, and whether the reducer is filled with lubricating oil.

3. Clean promptly after shutdown to prevent material drying, solidification, and affecting the next start-up.

4. After the machine is installed, do not start the machine before adding the grinding media.

A ball mill is a key equipment for further crushing materials after they have been crushed. It is widely used in the production of cement, silicate products, new building materials, refractory materials, fertilizers, ferrous and non-ferrous metal ore dressing, and glass ceramics, for dry or wet grinding of various ores and other grindable materials.

Test operation

After the ball mill is installed and inspected and qualified, it can be subjected to a no-load test run. The test run of the ball mill should be carried out by a skilled ball mill operator and strictly follow the ball mill safety operating procedures.

(1) The continuous running time of the no-load operation is not less than 12-24 hours. Any problems found during operation should be solved promptly.

(2) After the no-load test run is normal, the load test run can be carried out. The load test run should be carried out in stages. During the load operation, the feeding should be adjusted according to the discharge situation to avoid unnecessary wear and tear of the steel balls and cylinder lining.

1. Add appropriate materials and 1/3 of the steel balls (refer to the ball mill general drawing for the maximum ball loading) and run for 12-24 hours.

2. Add up to 2/3 of the steel balls and run for 24-48 hours.

3. According to the discharge situation of the ball mill, the output of qualified products, and referring to the actual ball loading of similar ore dressing plant ball mills, determine the reasonable ball loading of this ball mill and conduct a test run for at least 72 hours.

(3) The increase in the above load and the duration of the test run should be determined based on the running-in situation of the large and small gears and reducer gears (temperature rise, noise, tooth surface contact, etc.). Before the tooth surface contact accuracy reaches the design requirements, full-load operation is not allowed.

(4) During the test run, the cooling and lubrication systems should work normally. The main bearing, transmission bearing, and reducer temperatures should be normal.

(5) After running for 24-48 hours with 2/3 of the steel balls, all bolts should be checked and tightened again.

(6) The test run work should carefully record all items.